A unique piece need not cost a fortune. If you have a special anniversary coming up and want to mark it, send us an enquiry.

|

Commissions Welcomed A unique piece need not cost a fortune. If you have a special anniversary coming up and want to mark it, send us an enquiry. |

|

It is now July 2023 and I haven't updated this site for quite some time! I have, however, been designing a number of 'time-pieces' and some have been partially made but I recently actually completed one project and am close to completeing yet another. Many projects have fallen by the wayside simply because they didn't stand up to the scrutiny of the real world even though on the drawing board they looked more than viable. Some simply relied on small electric motors which turned out to be less than totally reliable, even with the addition of voltage control. One particular example perported to run at 100rpm from 6v - all the design work & calculations were based upon this premise but when the 6v was applied, it became obvious that it was running at more like 120 rpm. by adjusting the voltage to 5.2v I did get somewhere close but it became very temperemental. Not what I needed when the design had a scale model of both the Earth and the Moon attached. The Earth rotating on a 23.5° axis and the Moon taking 27.327 days to rotate once to within 20 seconds per year. This project made me somewhat deflated and it remains incomplete. Another project came to life after I read an article about Galileo's work on the Pendulum. The escapement he created looked simple enough and by now I had aquired a CNC machine which made the creation of complex shapes very much easier. I had also discovered the Reuleaux Polygons and I designed quite a large wooden clock incorporating both. Using a full length (1m) Pendulum made from Carbon Fibre, a Reuleaux Pentagon dial and a 2.5kg solid Lead driving weight. The idea was to make 4 of these to gift to some of my family. I did have one running for some hours but after a minor cosmetic ajustment it refused to perform for longer than a few minutes. Again, becoming dis-illutioned, all four remain languishing in a box awaiting some inspiration to take hold! Here's a photo of the one fully assembled and another of the Escapement |

|

|

Having been dis-illutioned with my attempts to get small motors to do the job efficiently, I returned to using commercial Quatrz movements. Being keen to bring something more than just creating a clock-face, attaching a Quartz movement & hands and calling that a craft work, I looked at driving a gear train from the minute hand spindle. Designing the train was not a difficult job but I found that if I also wanted a 'Seconds' hand then the torque required to drive such a train was beyond the capability of even quartz movements designated as 'Hi-Torque' and adding the 'complication' of a 'Day of the Week' dial made things even worse! This realization made me resort to accepting that the Seconds. Minutes & Hours should be taken directly from the three spindles provided by the movement. Adding the complication of a 'Day of the Week' wheel became the goal. This would be achieved by adding a driving gear to the hour spindle - behind the Hour Hand |

|

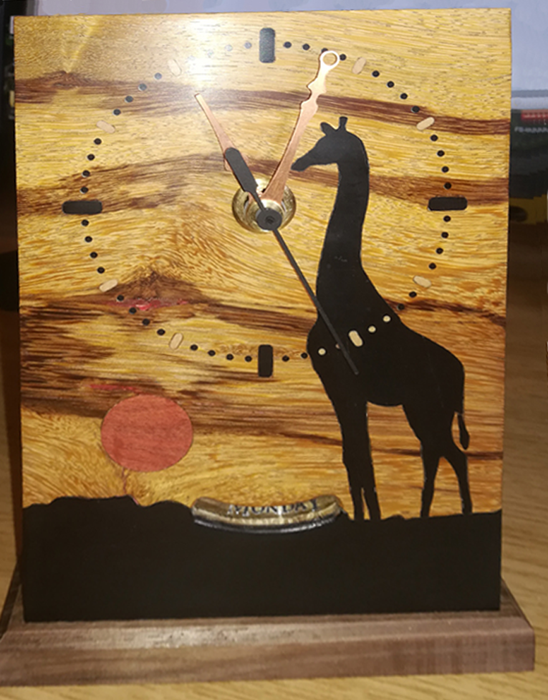

I had been enamoured of a photograph of an African Sunset which had a Giraffe in shilouette, this, coupled with the memory of a piece of Marble Wood I'd bought some while ago, started the creative juices flowwing which resulted in a 'pictorial' clock using Ebony & Padauk. |

|

Now I'd solved the issue of driving a Weekday Wheel from the hour spindle, I looked at refining the concept. I also wanted to lose the 'step-seconds'

so I bought some movements with 'Sweep' seconds. As ever, you solve one issue only to be confronted with another. - - - - -

These new movements have no space on the hour spindle to attach a gear since it is covered by the threaded sleeve which is used to

secure the movement to the dial. Un-daurnted, I looked at whether I could shorten the sleeve. Making a jig to hold the square quartz movement in my lathe I set about turning it down. All went well until I became somewhat cavalier at which point I removed most of the hour spindle!. I was marginally successful in creating a new spindle which could be fixed to the stub that was left. This worked, but on testing the movement with just a Seconds hand attached, it became clear that I had done far more damage than at first thought. The 'sweep' seconds was somewhat erratic, randomly stopping altogether. Fortunately, I had bought two similar - though marginally different - sweep seconds movements. The second costing about one third of the price of the one I'd ruined. It was also slightly thicker and with the time correction wheel on the opposite side !! - all little irritations causing a re-think to the case design. For the first clock with a week-day wheel (African Sunset), I'd put the day window at the bottom which worked well for the 'portrait' format, but for a my next effort I wanted a Reuleaux Pentagon shape which is essentially a square format - ie. a more 'normal' clock. This meant a complete re-think as far as the gearing was concerned. To get a day-wheel to rotate once per week means that there has to be a 14 : 1 ratio between the hour spindle and the day-wheel. I achieved this initially with a 30T gear driving a 60T gear which had a 25T Gear attached to drive the 175T day-wheel. This allowed the centre of the day-wheel to be positioned below the movement centre. To make the day-wheel concentric with the movement I had to be somewhat lax as far as the gear centres were concerned. I still needed the 25/175 pairing to give me a 7:1 ratio but the PCD of gears is direcrtly related to the number of teeth (and the MOD) so I needed a 2:1 ratio paiing that had the same centre distance as the 25/175 pair. Now, I'm using a MOD 0.5 Cycloidal Hob to make my gears so the PCD of a 175T gear is 87.5mm and the 25T is 12.5 so the ideal centre distance between those two is 50mm (half that sum) though in reality that might cause some binding so I design with a 0.2mm clearance making it 50.2mm. The closest pairing of a 2:1 ratio I could find is a 132T/66T which has an 'ideal' centre distance of 49.5mm. Now the MOD 0.5 Hob that I have is 'non-topping' which means that there is a small clearance between the nominal OD of the gear and the root of the Hob so by making the gear blank OD 0.5mm larger, I can gain that extra 0.5mm with little consequence, the PCD is not changed but the teeth are a little longer so will still mesh with the slightly larger centre distance - - - Result! |

|

I started this 'EDIT' by saying that I was close to completing another project - well, it's now about four hours later and that project IS complete! |

|

|

|

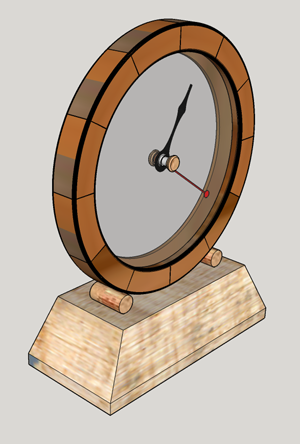

This is the next project and, as you can see, it is fully designed. Materials have been sourced but I haven't yet started to make the components.

There will be no 'Day-wheel' and the seconds will only show in a small side window on a dial 50mm dia. as numbers. I do hope it will not take me another three years before my next 'Edit' ! |

|

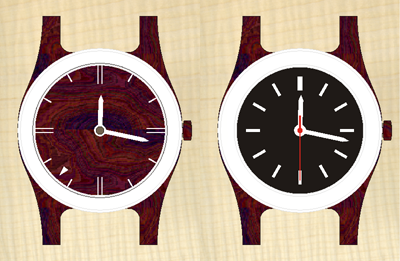

I recently (this was written in 2005!!) received a sample of an Ivory Substitute manufactured in Germany called "Elforyn"® which I intend to combine with Rosewood or Ebony (or both). | |

|

BIG DATE

This design uses a man-made Tortoiseshell alternative to house a Citizen Quartz 'Big Date' movement. The seconds hand is a simple pointer on a clear Plexiglas® disc. The Hour markers are Nickel-Silver and the minutes are 0.25mm wide slots cut into the Rippled Sycamore dial filled with Garnet Shellac. May 2006 The 'Big Date' Movements are ordered but delivery is currently unknown due to it being a very new Movement from Citizen. When they arrive the first watch using them will be Black Palmira with Shark-skin Strap, Stainless Steel Deployant Clasp and Orange Swampwood Veneer Dial. The Citizen/Miyota 1M52 movement hs now arrived so click here to see the construction progress. |

|

|

A further Ivory alternative based design giving more prominence to the 'white'.

The strap for this will be white Calf.

May 2006 The blank for this case is also made |

|

|

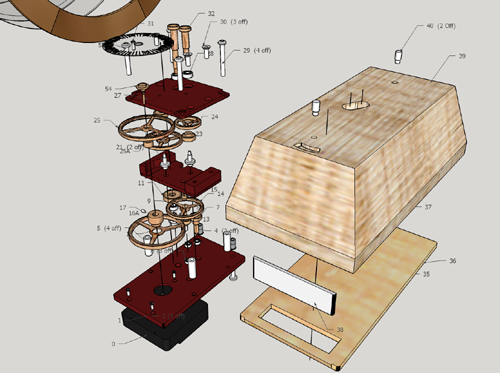

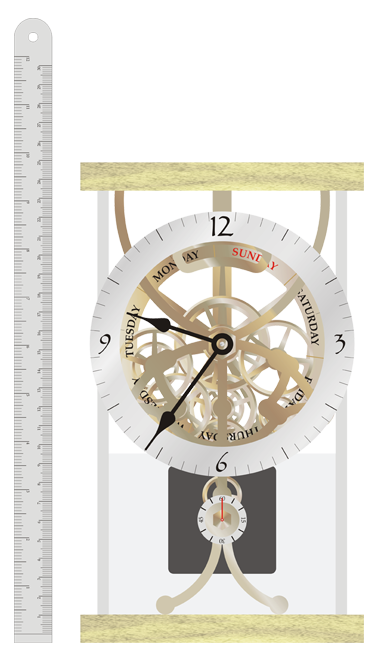

On hearing about the engagement of my Niece I rashly said that I would make a clock for the occasion of her marriage.

My thoughts were something along the lines of a Sycamore and Walnut case with a Radio corrected Quartz movement but

knowing her flare for design I wanted her to have some input. When she came back with "Something modern with Stainless steel and/or brass . . . Oh, . . . it would be nice if you could see the movement" . . . I had to take a step back and re-think. My intial thoughts were that 'Skeleton Clocks' take a serious amount of time to manufacture and although a wooden skeleton clock was my original inspiration for getting into this field of endevour the idea that I could even attempt to make one before July 2007 was inconceivable Shortly after this a 'flyer' came in my post and dead centre on the front was a skeleton clock movement ready made complete with dial/hands/case which I could quite easily incorporate into a new case of my design. I bought two (just in case) and proceded to investigate the best way to extract just the movement. Within 15 minutes I had destroyed the first - but I now had no compunction about taking the whole movement apart. I knew it was a quartz movement but was surprised to see how simple the driving force was. Thoughts now turned to the posibility that I could make a quartz unit with a solenoid acivated each second and drive my own gears - the fact that I didn't have any knowledge of quartz crystals or a means of making gears was secondary - there now seemed a way that I could in fact conform to all the criteria that had been imposed upon me! As an aside, I'm amazed to find that this cheap skeleton movement is keeping extraordinary good time - after three weeks the second unit is about 2 seconds fast. I now set about investigating quartz crystals and solenoids but quickly found that 'experimental electronics' is all but dead in he UK and any components that I might get were going to be 'silly money' or from the USA (with all the problems that would entail). It occured to me that I already had access to a ready built quartz movement and not only that it was a radio corrected one (as used in 'The Giant'). It seemed that instead of puting a hand on the minute spindle I could put a gear and that could then drive a train essentially 'reverse engineering' all the hand movements. There would be issues of friction and torque but if I took all measures to minimize the friction then the amount of torque available would not be a problem. Friction is caused by rubbing between mating components and under normal conditions gearing ought to be in constant contact to reduce 'backlash'. In clocks of course backlash is not a problem because power is applied in only one direction (even in those which are designed to run backwards) so actually designing to include extra backlash (space between gears) is perfectly acceptable. After many hours drawing gears of appropriate ratios and suitable 'skeletal' plates to hold them in place I have now created my third design which I am now preparing to manufacture. |

|

|

Update - March 2007

Many spindles and gears have been cut to test the vibility of driving this gear train 'in reverse'. Prototype plates have been made from Aluminium with spindle breaings in Brass inset and the whole of the seconds train is under test. The good news is that it works . . . . . . after a fashion . . . . . . . for a few days it seemed that it would not work at all because it would stop after less than 2 minutes but with just a 'tap' it would start again. The real issue is that the seconds are not indicated evenly - often there are three seconds delay, sometimes two. So overall I think that the movement does not have sufficient torque to drive the seconds hand from the minute hand. Another isue is the overall size of the finished unit - at over 12" high I think it is too much. I've now re-designed it (Skeleton 4) using a 0.5MOD Cycloidal Hob which should have a number of advntages but in addition I'm now going to drive everything off the seconds spindle of the Quartz Movement. My original objection to this approach was that I could not thread the spindle but I now believe that I can make an extention to the movement spindle which is a friction fit and that will have the seconds hand attached directly to the other end - no 'centre seconds' but I consider that a small price to pay. To even up the gearing, I've added a 'Weekday' complication. |

|

|

Update - December 2007

Time in the workshop has been constrained by the needs of my fee-paying customers, so little has been done since June The part completed unit was displayed at the wedding, the Bride & Groom were suitably surprised and appreciative of the design which no longer has the heavy top with stainless steel support pillars. During assembly it was discovered that some of the gears had not been cut deeply enough - despite accurate measurments being taken of the root diameter - so I had to find a better way to determine the required depth. Simply feeding the hob onto the gear blank, checking contact with a feeler gauge and then feeding until the calculated root diameter had been achieved was not accurate. I determined that feeding to the calculated tooth depth (by reference to a plunge action clock) after contact, without taking account of the measured root diameter was much better. Six new gears were cut and a further 2 after being destroyed when pressing onto the spindles. Three new spindles had to be made due to miss-allignment during the process of fitting the gears causing them to be bent Another spindle needs to be made to replace one I've since found to be bent and I hope to get back in the workshop during January. Watching the corrective action of the other Radio-Controlled movement in the 'Giant Watch' I've noticed that there is a tendency for it to roll forward by 12 hours to correct a small 'forward' error. ie. if the received time signal is 12:00 but the current display is 12:00:30 then it rolls forward 11H 59M 30S - This would be a disaster as far as the 'Day Wheel Display' is conserned since it would roll forward half a day! In view of this I've decided to dispense with the accuracy of Radio Control and fit a simple quartz movement. |

|

Giant Watch

Giant Watch

|

History

History

|

Current Work

Current Work

|

Home

Home

|

Materials

Materials

|